Nhiệt điện trở NTC: Hằng số thời gian & Thời gian đáp ứng

Aug 21, 2025Khi thử nghiệm hoặc áp dụng nhiệt điện trở NTC, hai thông số thường xuất hiện: hằng số thời gian nhiệt (τ) và thời gian phản hồi. Cả hai đều mô tả phản ứng nhiệt độ động của cảm biến, và mặc dù có liên quan chặt chẽ, chúng được định nghĩa khác nhau. Để hiểu mối quan hệ của chúng, cần xem xét cả định nghĩa khái niệm và mô hình toán học.

1. Định nghĩa chính

1)Hằng số thời gian nhiệt (τ): Hằng số thời gian nhiệt định lượng quán tính nhiệt của cảm biến. Hằng số này được định nghĩa là: Thời gian cần thiết để cảm biến đạt 63,2% tổng chênh lệch nhiệt độ giữa trạng thái ban đầu và môi trường ổn định mới khi chịu sự thay đổi nhiệt độ đột ngột.

τ nhỏ hơn có nghĩa là nhiệt điện trở phản ứng nhanh hơn với những thay đổi nhiệt độ. τ lớn hơn có nghĩa là quán tính nhiệt lớn hơn và phản ứng chậm hơn. Các yếu tố ảnh hưởng τ: Kích thước cảm biến (cảm biến nhỏ hơn → nhỏ hơn τ)Vật liệu đóng gói (độ dẫn nhiệt tốt hơn → nhỏ hơn τ)Môi trường xung quanh (chất lỏng thường tạo ra chất lỏng nhỏ hơn τ hơn không khí do độ dẫn nhiệt cao hơn)

2)Thời gian phản hồi: Thời gian phản hồi là một tham số hướng đến ứng dụng thực tế.

Được định nghĩa là: Thời gian cần thiết để đầu ra của nhiệt điện trở đạt đến một tỷ lệ phần trăm nhất định của nhiệt độ cuối cùng (ví dụ: 90%, 95%, 99%).

Các ngành công nghiệp khác nhau áp dụng các tiêu chuẩn khác nhau: Các thiết bị y tế thường sử dụng thời gian phản hồi 90%. Các ứng dụng công nghiệp có thể yêu cầu 95%. Các ứng dụng có độ chính xác cao đôi khi sử dụng 99% hoặc cao hơn. Do đó, thời gian phản hồi là tương đối và phụ thuộc vào tỷ lệ ổn định đã chọn.

2. Mối quan hệ toán học

Phản ứng nhiệt của một Cảm biến NTC có thể được xấp xỉ bằng mô hình hàm mũ bậc nhất:

T(t)=T0 +(T∞−T0)·(1−et/τ)

Ở đâu:

T(t): nhiệt độ cảm biến tại thời điểm t

T0: nhiệt độ ban đầu

T∞: nhiệt độ ổn định cuối cùng

τ: hằng số thời gian nhiệt

Các thời điểm chính:

Thời gian | Tỷ lệ thay đổi nhiệt độ (phần trăm đạt được chênh lệch nhiệt độ mục tiêu) | Các tình huống tương ứng (định nghĩa thời gian phản hồi) |

t=τ | 63,2% | Định nghĩa của τ |

t=2τ | 86,5% | “Phản ứng nhanh” trong một số trường hợp |

t=3τ | 95,0% | Tiêu chuẩn công nghiệp |

t=5τ | 99,3% | Độ chính xác cao |

t=7τ | 99,91% | Ổn định cơ bản hoàn toàn |

Do đó: 90% phản hồi ≈ 2,3τ;95% phản hồi ≈ 3τ;Phản hồi 99% ≈ 5τ.

Thời gian phản hồi về cơ bản là bội số của τ, tùy thuộc vào tiêu chí ổn định.

3. Tóm tắt mối quan hệ

1) Nền tảng so với Ứng dụng: Hằng số thời gian nhiệt (ττ) là tham số cơ sở; thời gian phản hồi được suy ra từ tham số này.

2) Tỷ lệ thuận: Bất kỳ yếu tố nào làm giảm τ (ví dụ, kích thước nhỏ hơn, dẫn nhiệt tốt hơn) cũng làm giảm thời gian phản hồi theo tỷ lệ.

3) Cố định so với Tương đối: τ là một đặc tính cố định của nhiệt điện trở và môi trường xung quanh; thời gian phản hồi là tương đối và phụ thuộc vào định nghĩa (90%, 95%, 99%, v.v.).

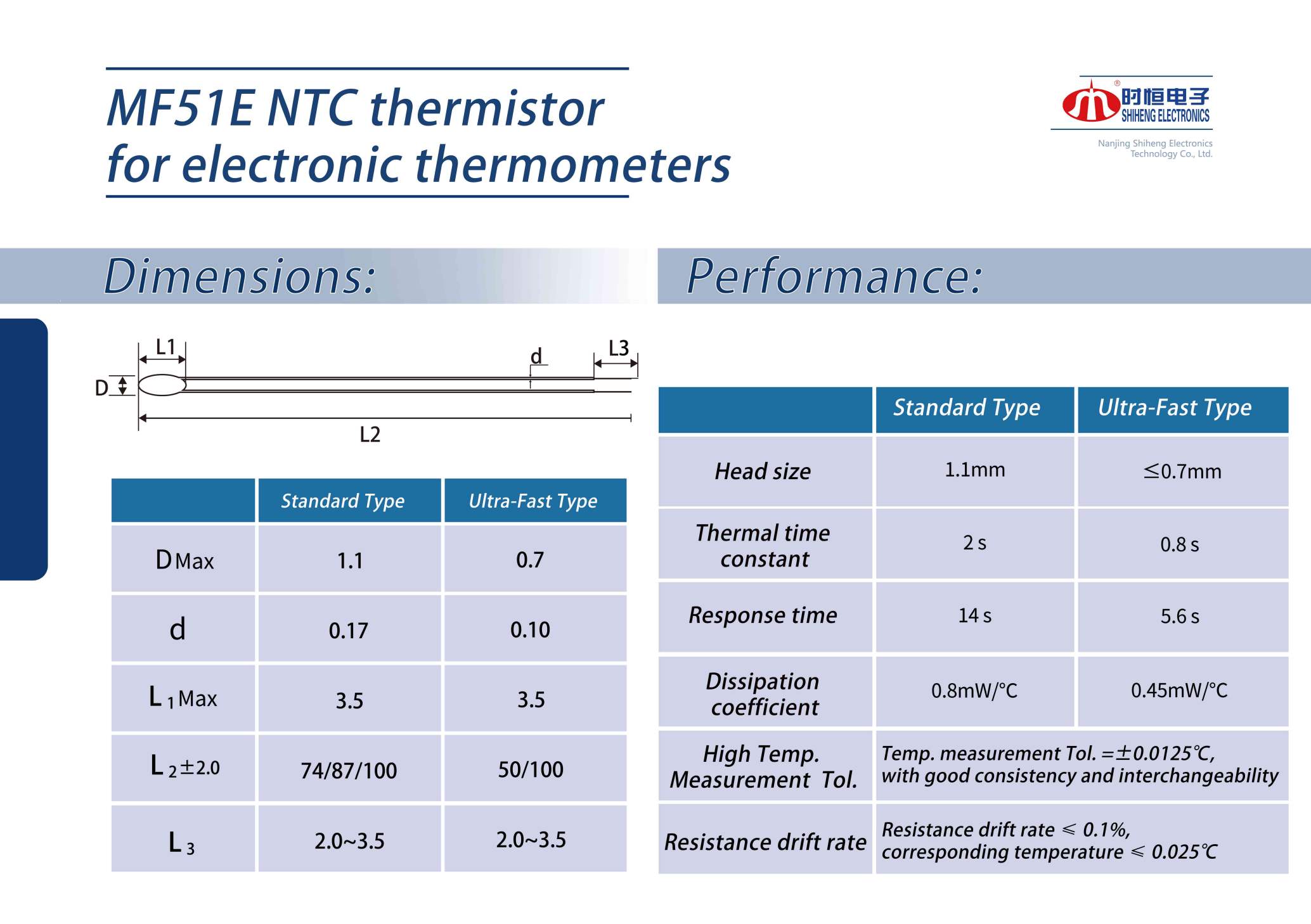

4. Ví dụ – Shiheng Electronics MF51E 503F3950

|  |

Hằng số thời gian nhiệt τ = 0,8 giây

Thời gian phản hồi 90% ≈ 2,3 × 0,8 = 1,84 giây;Thời gian phản hồi 95% = 3 × 0,8 = 2,4 giây;Thời gian phản hồi 99% = 5 × 0,8 = 4,0 giây;Thời gian phản hồi 99,91% = 7 × 0,8 = 5,6 giây.

Nhiệt điện trở NTC siêu nhanh này có thể đo nhiệt độ cơ thể chính xác trong vòng ~5,6 giây, lý tưởng cho nhiệt kế y tế.

5. Tại sao nên chọn Shiheng Electronics?

Với hơn 20 năm kinh nghiệm, Shiheng Electronics cung cấp:

✔ Nhiệt điện trở NTC có độ chính xác cao, phản ứng nhanh

✔ Độ đồng nhất tuyệt vời và độ tin cậy lâu dài

✔ Kích thước nhỏ gọn và cấu trúc ổn định cho nhiều ứng dụng khác nhau

✔ Các giải pháp đã được chứng minh cho thiết bị điện tử tiêu dùng, thiết bị y tế, hệ thống năng lượng và điều khiển công nghiệp

Của chúng tôi dòng MF51E phản ứng nhanh đáp ứng nhu cầu ngày càng tăng về cảm biến nhiệt độ dưới 6 giây trong các ứng dụng y tế và tiêu dùng.

Tìm hiểu thêm về nhiệt điện trở NTC và các giải pháp ứng dụng của chúng tôi trên trang web chính thức của Shiheng Electronics hoặc liên hệ trực tiếp với nhóm của chúng tôi để được hỗ trợ kỹ thuật.