Khoa học vật liệu nhiệt điện trở ảnh hưởng đến hiệu suất cảm biến như thế nào?

May 14, 2025Khoa học vật liệu nhiệt điện trở tác động đến hiệu suất cảm biến như thế nào? Khi nói đến cảm biến nhiệt độ, hầu hết các kỹ sư tập trung vào ứng dụng, độ chính xác hoặc kiểu đóng gói. Nhưng đằng sau mỗi nhiệt điện trở hiệu suất cao có một nền tảng thường bị bỏ qua: vật liệu gốm. Cho dù bạn đang thiết kế cho hệ thống ô tô, y tế hay công nghiệp, việc hiểu được khoa học vật liệu đằng sau nhiệt điện trở có thể là chìa khóa để mở ra hiệu suất tốt hơn, tuổi thọ dài hơn và kết quả nhất quán hơn.

Tại sao thành phần gốm lại quan trọng?

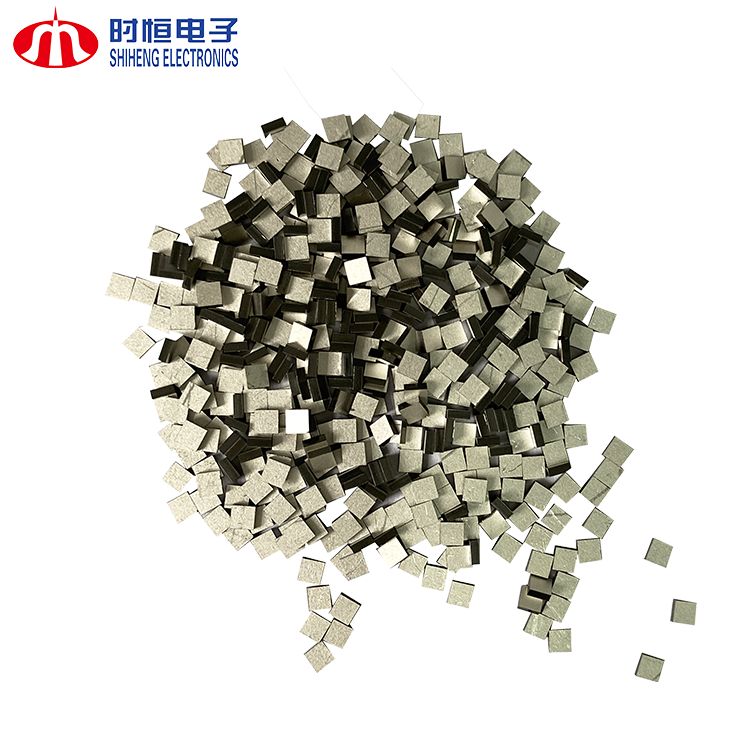

Nhiệt điện trở NTC thường được làm từ oxit kim loại thiêu kết — phổ biến nhất là sự kết hợp của oxit mangan, niken, coban và đồng. Tỷ lệ cụ thể và cấu trúc hạt của các vật liệu này ảnh hưởng trực tiếp đến:

Tại Nanjing Shiheng, chúng tôi đã đầu tư mạnh vào công nghệ nung kết và chế tạo gốm tiên tiến để chế tạo ra các nhiệt điện trở có hiệu suất đáng tin cậy và độ chính xác cao trong điều kiện khắc nghiệt.

Những cải tiến chính trong vật liệu nhiệt điện trở. Sau đây là một số tiến bộ về vật liệu ảnh hưởng trực tiếp đến hành vi của nhiệt điện trở:

1. Chuẩn bị bột ở quy mô nanomet. Quy trình độc quyền của chúng tôi tạo ra bột gốm siêu mịn với kích thước hạt đồng đều, đảm bảo:

2. Kiểm soát thiêu kết tự động. Các quy trình thiêu kết được kiểm soát chính xác dẫn đến:

3. Giao diện gốm-điện cực phù hợp. Điện cực không phù hợp có thể tạo ra điện trở tiếp xúc hoặc trôi dạt dài hạn. Nhiệt điện trở của chúng tôi sử dụng kim loại hóa tối ưu để đạt được:

Điều này ảnh hưởng thế nào đến hiệu suất?

Sau đây là cách khoa học vật liệu của chúng tôi chuyển thành những lợi thế thực tế:

Tham số | Tác động của vật liệu tiên tiến |

Sức đề kháng Dung sai | ±1% hoặc tốt hơn, ngay cả ở khối lượng lớn |

Độ chính xác nhiệt độ | ±0,1℃ (0–70℃); lên đến ±0,01℃ trong các mô hình chính xác |

Độ bền | Hơn 100.000 chu kỳ nhiệt không hỏng |

Bằng cấp ô tô | Đã được AEC-Q200 chấp thuận cho MF51, MF52, MF58, Dòng MF59 |

Sức đề kháng của môi trường | Đã vượt qua thử nghiệm 85℃/85% RH + nước sôi + điện áp |

Được thiết kế cho nhu cầu của ngành công nghiệp hiện đại. Nhiệt điện trở hiệu suất cao bắt đầu bằng vật liệu hiệu suất cao. Cho dù bạn đang thiết kế đầu dò nhiệt độ cấp y tế, hệ thống giám sát pin cho EV hay mạch bù nhiệt độ trong thiết bị IoT, thì gốm sứ đều quan trọng.

Bạn có muốn thấy sự khác biệt về vật liệu khi thực hiện không? Liên hệ với chúng tôi để lấy mẫu, bảng dữ liệu hoặc tư vấn phát triển tùy chỉnh.